The Ultimate Guide to Finding Reliable Welding Inspection Milwaukee Professionals

The Ultimate Guide to Finding Reliable Welding Inspection Milwaukee Professionals

Blog Article

Discovering the Different Methods and Specifications of Welding Inspection for Getting Compliance and Reliability in Engineering Applications

The importance of welding examination in design applications can not be overstated, as it serves as an important guard for guaranteeing architectural stability and conformity with market requirements. Different approaches, consisting of visual evaluation and progressed non-destructive screening techniques, give essential insights into the quality of welds. Furthermore, adherence to established regulative requirements such as those from AWS and ASME establishes a structure for responsibility and excellence. The landscape of welding examination is continually evolving, triggering a more detailed assessment of arising techniques and their effects for engineering reliability. What might these developments involve for future projects?

Value of Welding Evaluation

Welding examination plays an essential function in ensuring the stability and safety of bonded structures. The value of welding evaluation can not be overemphasized, as it offers as a safeguard against possible failures that might result from inadequate welding techniques.

Moreover, welding examination is necessary for preserving quality assurance throughout the welding process. It guarantees that the welds fulfill the necessary mechanical and physical residential or commercial properties required for their designated applications. Routine examinations additionally foster a society of accountability and continuous renovation within welding procedures, motivating adherence to ideal techniques and market criteria.

In regulated sectors such as building, aerospace, and manufacturing, rigid welding evaluation methods are mandated to abide by legal and safety and security requirements. Inevitably, effective welding assessment not just protects human life and residential property but additionally enhances the durability and reliability of welded structures, making it an indispensable element of design and building.

Common Welding Inspection Approaches

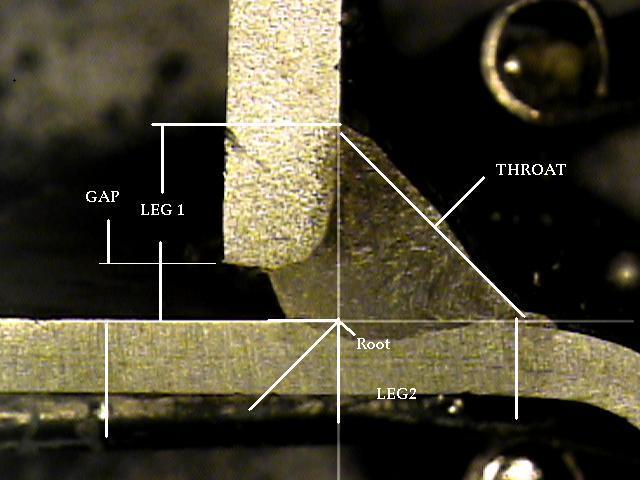

A selection of inspection approaches are used to assess the top quality and honesty of welds, each customized to find certain kinds of problems. Amongst the most typical techniques is aesthetic inspection, which entails a comprehensive evaluation of the weld surface to recognize noticeable imperfections such as fractures, damages, and insufficient fusion. This technique is often the primary step in the inspection process because of its simpleness and cost-effectiveness.

Another commonly made use of method is radiographic inspection, where X-rays or gamma rays pass through the weld to expose internal problems. This method is particularly reliable for finding porosity and incorporations within the weld product. Ultrasonic screening utilizes high-frequency audio waves to recognize internal defects, providing a detailed analysis of the weld's honesty.

In addition, magnetic particle examination is made use of for ferromagnetic materials, enabling for the detection of surface area and near-surface issues by using electromagnetic fields and observing particle patterns. Color penetrant testing involves applying a liquid dye to the weld surface area, revealing fractures and various other interruptions upon examination (Welding Inspection Milwaukee). Each of these approaches plays an important duty in ensuring weld top quality and compliance with industry criteria

Non-Destructive Examining Techniques

Non-destructive screening (NDT) techniques are important tools in the assessment of weld top quality, permitting assessors to examine the honesty of bonded joints without creating damages to the materials. Various NDT techniques are used to identify prospective issues, guaranteeing that welds fulfill the required requirements for safety and security and performance.

Among the most widespread techniques is ultrasonic screening (UT), which makes use of high-frequency sound waves to discover internal flaws such as spaces or cracks. Radiographic testing (RT) utilizes X-rays or gamma rays to generate pictures of welds, exposing any discontinuities within the material. Magnetic fragment screening (MT) works for detecting surface area and near-surface defects in ferromagnetic products through the application of magnetic areas and contrasting bits.

Fluid penetrant screening (PT) is one more extensively used technique that entails using a dye to the surface of the weld, which leaks right into any type of cracks, making them visible under ultraviolet great site light. Each of these approaches supplies distinct benefits and limitations, and the option of a suitable method is vital to attaining exact assessments of weld integrity. Inevitably, the implementation of NDT techniques dramatically adds to the reliability and safety of engineering applications.

Governing Specifications and Compliance

In the world of welding evaluation, adherence to regulatory requirements and compliance is extremely important to make certain the safety and security and integrity of bonded frameworks (Welding Inspection Milwaukee). Different organizations, consisting of the American Welding Society (AWS), the American Society of Mechanical Engineers (ASME), and the International Company for Standardization (ISO), have developed guidelines that regulate welding practices and assessment procedures. These requirements supply a framework for high quality guarantee, detailing the needed qualifications for inspectors and the approaches for analyzing weld honesty

Compliance with these governing standards not only boosts the structural stability of bonded assemblies but likewise minimizes dangers linked with failures, which can have have a peek here devastating repercussions. Assessments need to be executed using defined treatments, including visual, ultrasonic, and radiographic methods, to make certain that welds fulfill defined criteria.

Furthermore, adherence to these standards is often called for by regulation, especially in markets such as construction, production, and aerospace. Normal audits and certifications are necessary to preserve compliance, thereby fostering a culture of safety and security and quality within organizations. Eventually, governing standards and conformity serve as the backbone of trustworthy welding evaluation practices, making certain that crafted structures fulfill both performance assumptions and security demands.

Finest Practices for Welding Examination

While maintaining conformity with regulatory requirements is vital, implementing finest techniques for welding inspection additionally boosts the safety and integrity of welded frameworks. Effective welding evaluation starts with complete planning, which consists of understanding the specific needs of each job and making sure inspectors are well-trained in applicable approaches and criteria.

Utilizing a thorough inspection list aids to make find out sure all essential aspects are examined, such as weld dimension, infiltration, and aesthetic flaws. Non-destructive testing (NDT) methods, such as ultrasonic or radiographic testing, should be employed where appropriate, providing a more in-depth evaluation of weld top quality without compromising the integrity of the products.

Paperwork plays a considerable function in best techniques; keeping precise records of inspections, consisting of pictures, examination results, and compliance records, makes sure responsibility and assists in future evaluations. In addition, fostering a society of open interaction between welders and assessors can bring about very early recognition of prospective issues, advertising immediate rehabilitative actions.

Verdict

In summary, the implementation of extensive welding examination approaches and adherence to developed requirements are important for making certain compliance and dependability in engineering applications - Welding Inspection Milwaukee. Techniques such as visual examination, radiographic testing, and ultrasonic screening serve as crucial tools in identifying problems and preserving quality guarantee. By fostering a society of accountability and quality, organizations can improve the integrity and long life of bonded structures, eventually contributing to the security and efficiency of design projects

Different methods, consisting of aesthetic evaluation and progressed non-destructive screening strategies, provide necessary understandings right into the quality of welds.Welding evaluation plays a critical function in making certain the stability and safety of bonded structures.A selection of examination techniques are utilized to assess the quality and honesty of welds, each customized to identify certain kinds of flaws.An additional widely utilized method is radiographic evaluation, where X-rays or gamma rays permeate the weld to expose internal defects.In the realm of welding inspection, adherence to regulatory requirements and conformity is vital to make certain the safety and reliability of bonded frameworks.

Report this page